Students: Jim Kuivenhoven|![]() , Mikko Itäluoma|

, Mikko Itäluoma|![]() , Aleksi Mutru|

, Aleksi Mutru|![]() , Jaap van Rekom|

, Jaap van Rekom|![]()

Company introduction

Metazet is a global market leader of innovative total solutions for the horticultural sector. Metazet offers custom production of cultivation systems on location, to logistics concepts and realisations for more convenience and more efficient internal transport.

Current situation

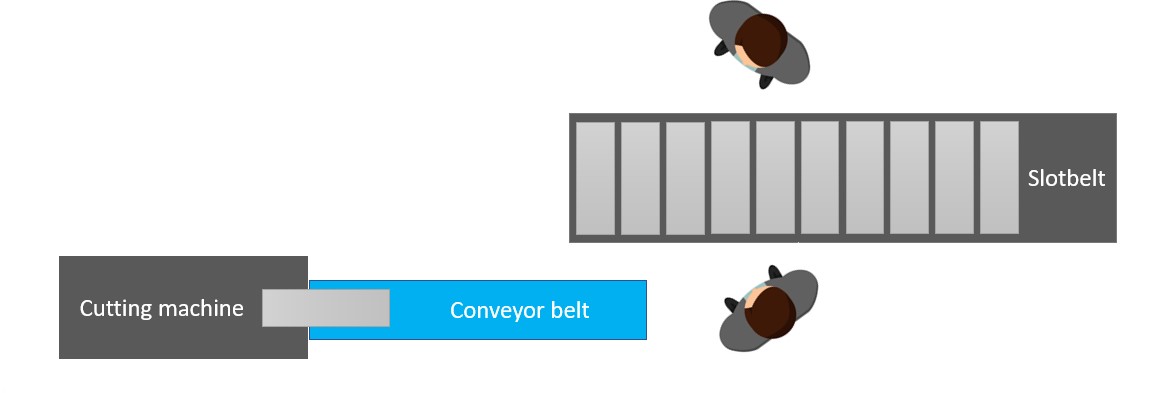

At Metazets production they are manufacturing steel plates that are used to assembly tube rail systems. This manufacturing process is almost fully automatized except for one part, which is still done by hand. This part comes down to moving the plates from the machine that produces the steel plates to an assembling and packaging line. Currently the worker does this by grabbing a plate from a conveyor belt and places the plate into a slotted conveyor belt where he, at the same time, places a support part to the plate. The assembly then moves to packaging. This all happens in a two seconds time span, so the worker has to be motorically very skilled to be able to do it. This is labour-intensive and it is hard to find workers to do the job as it is draining work.

Goals and challenges

We started working on this project with a goal to automate placing of plates that can vary in length. This will reduce the workload of the workers and allows future automation to be done. The project was the first part of a two phased project to automate the whole production line, so the second goal will be to create a solution that will automate the assembling of the supports as well.

The challenges in automating this production:

- High speed of production

- Continuous nature of the production

- Integrating with current production

- Produced steel plates vary in length

Difficulties we faced during our project:

- Delivery times of components, which resulted us replacing a linear gantry with a pneumatic cylinder

Our solution

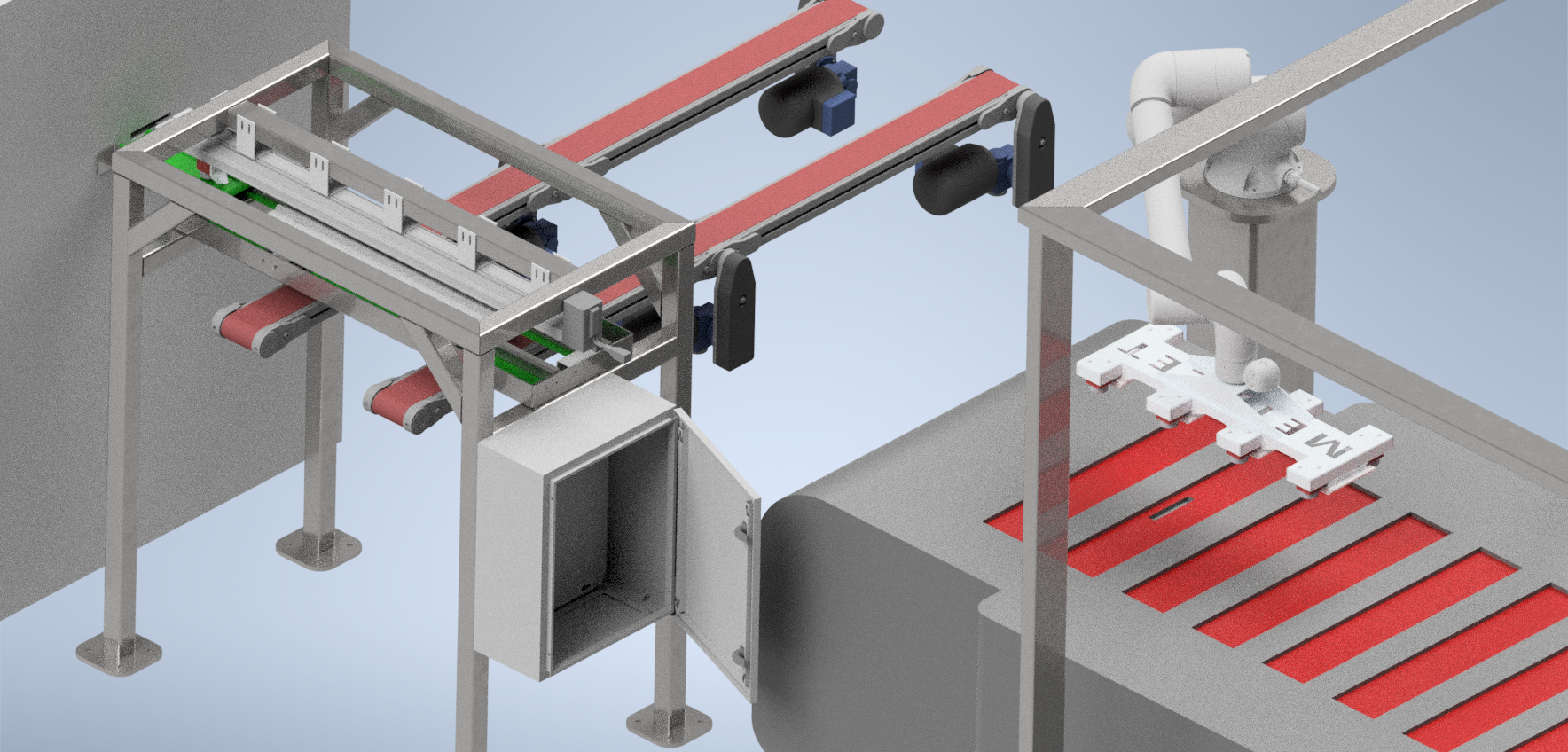

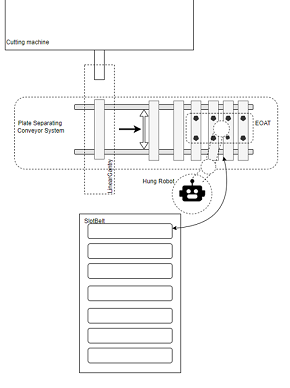

During the past 10 weeks we have created a solution that overcomes the challenges of the production. We came up with a solution that pulls the plates out of the cutting machine and drops them in a controlled manner onto a lower platform. Then at the moment when the plate is completely stationary on the lower platform, the platform opens up and lets plates fall onto a conveyor belt. The conveyor belt then lines the plates up in a good formation for the robot to pick them up and transfers them into the assembly line. Our solution consists mainly of four different parts and is controlled via Beckhoff Programmable Logic Controller (PLC), which communicates with the cutting machine, robot and the assembling line. The different parts of our system are getting introduced in the following paragraphs.

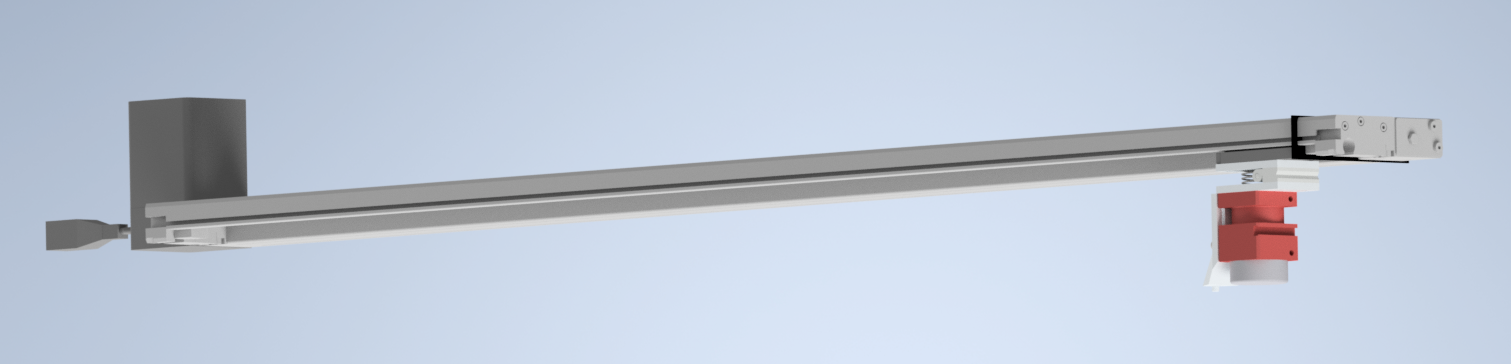

1st part, The Plate Extraction Module:

- Grabs the plate from the cutting machine with a special tool attached to a linear gantry

- Pulls the plate out of the machine and makes room for the next plate

- Releases the plate to drop onto the next module

*Linear gantry did not arrive on time so we used pneumatic cylinder instead in the setup*

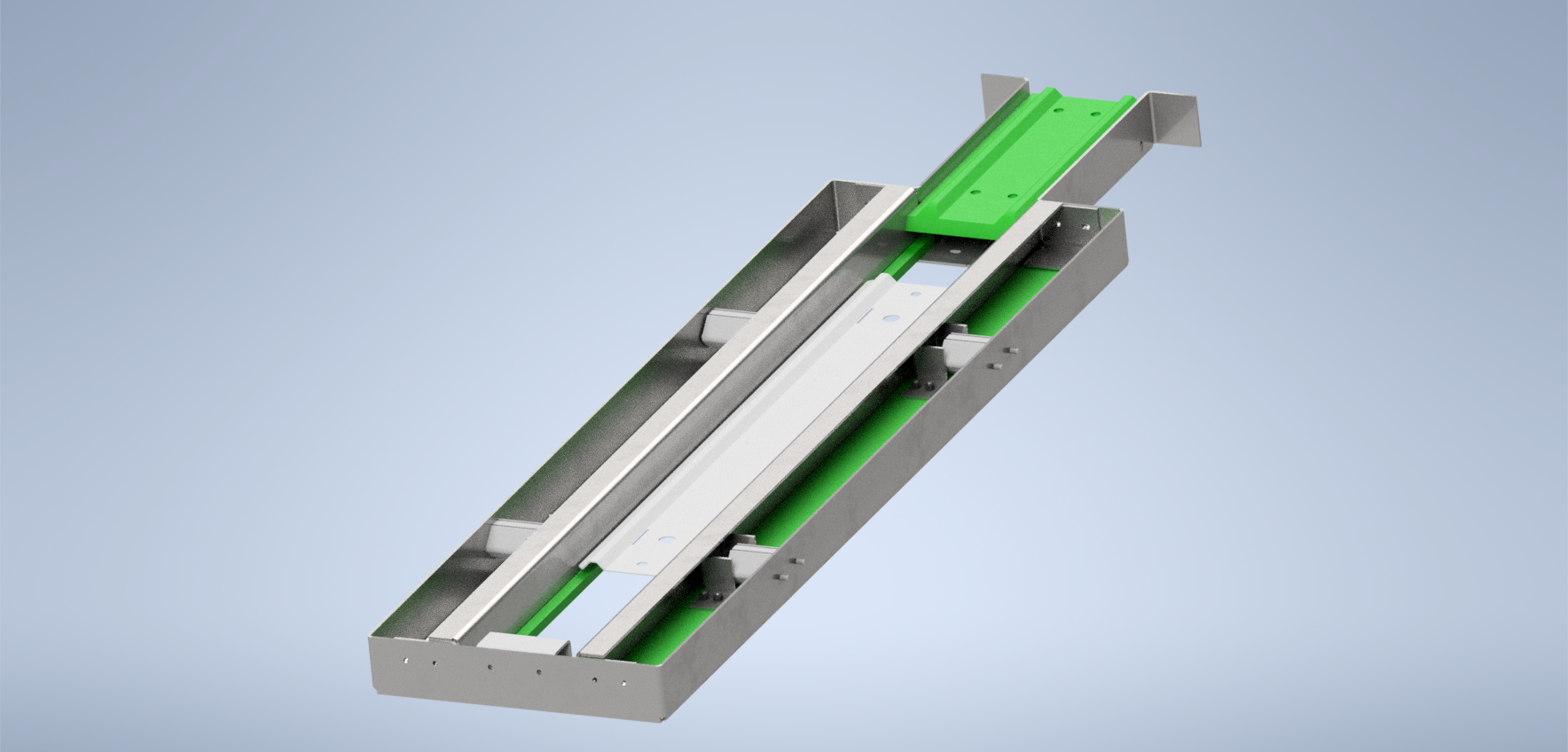

2nd part, The Dropping Module:

- Catches the released plate on a platform called the “gates”

- The gates move out of the way, which makes the plate drop onto the conveyor belt

3rd part, The Conveyor Belt:

- Moves the dropped plate closer to assembling line

- Creates specified amount of space between plates

- Transfers and align them for the robot pick up place

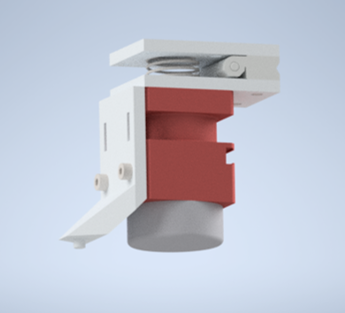

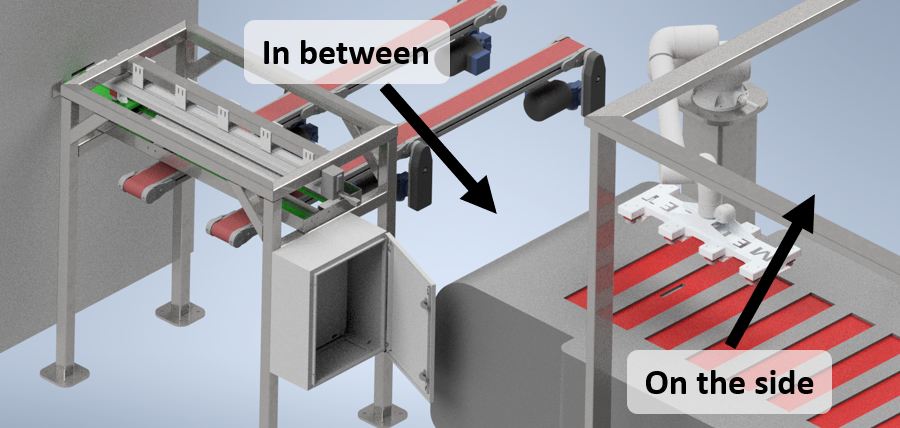

4th part, The Robot

- Grabs the plates from the conveyor with a special tool

- Places the plates to assembling lines slotted conveyor

Control and communication

The communication and control between the different components and other machines within the system is done by a Beckhoff PLC. This programmable logic controller (PLC) handles the control of all the modules, including The plate extraction module, conveyor belt, and robotic arm. It also communicates with the other machines in the production line, ensuring that all the components work together smoothly and robust.

For programming the automated functioning of our system we used Sequence Function Chart (SFC). Which waits for a starting signal from a communication bus to start the sequence to execute all the control of the modules with correct timings.

All of the different parts and components of the system can be controlled via a Human Machine Interface (HMI). We made a screen for sequence control and one for manual control screen, to control the components manually. These screens allow for easy monitoring, control of a process and making it simple to test the modules.

We made the HMI work wirelessly so the operator of the system can easily connect any device (that can access a Wi-Fi and a browser) to the system and use it as an HMI.

The Future of our solution

During our concept phase we thought outside of our project scope and designed a solution where the company can later add a buffer to the system to increase the efficiency of the process.

Second of all, the pneumatic cylinder (which pulls the plates), will be replaced to a linear gantry. This enables the system to work with different sized plates and improves efficiency by adding speed.

End Results

Our goal was to make a production ready concept that eases the workers labour and provides a base for future automation. The concept consists of 4 modules, the plate extraction module, the dropping module, the conveyor belt and the robot. Each module will transfer the plate in a controlled matter with the end result of placing the plates into the slotted assembly line. Through communication between our setup and the cutting machine, our setup was able to be placed in to the real setup. This setup was really meant as a test setup to showcase that the concept functions, and can in the future be further worked out to a production ready setup. This also includes the possibility to eventually automate the placement of the support pieces to fully automate the whole production line and remove the labor of 2 employees. This with the increase in labor cost and the shortage in employees, would result as a big benefit to the company.

Acknowledgment

As a group, we want to thank all the people at Metazet and at The Hague University of Applied Sciences, who helped us to overcome challenges during our project.

Special thanks belong to Ronald Boeters, Jeroen Stijger and Remco van Andel from Metazet. Thank you for providing us your resources and expertise!

We also want to give acknowledgment to our wonderful teachers Thijs Brilleman and Mathijs van der Vegt for guiding and supporting our path.