Students:

Daniel Tacoma: Daniel Tacoma | LinkedIn

Jelle van Haaster: Jelle van Haaster | LinkedIn

Arjan van der Knaap: Arjan Van Der Knaap | LinkedIn

Maarten van Geest: Maarten van Geest | LinkedIn

A solid introduction

A few months ago, we went to Flower Direct, a company which processes flowers from different flower growers all over the world.

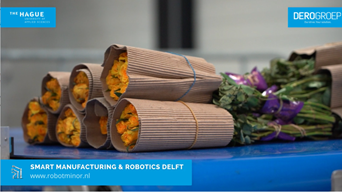

The company imports flowers from foreign countries, roses for example. These flowers come in by the box whereafter the flowers need to be cut and sleeved.

Though the handling of picking up the flowers and putting them in the supply conveyor belt for the sleeving machine is still performed manually.

However nowadays the employees needed for this job are harder to find than ever before.

“As the need for employees still continues to rise, a lasting solution is needed.”

But this is where we come in.

We’ve made a solution for our costumer Flower Direct, which meets the requirements of the costumer.

A solution that consist of picking the flowers at a high rate and where just one person is required to substitute 3 employees.

A solution that fits

Right, a solution that fits. But what exactly does that mean?

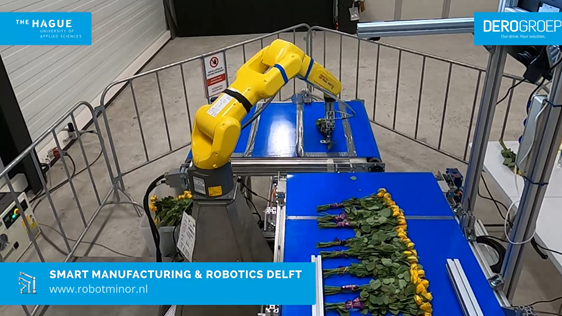

It means we’ve developed a solution where different flowers, mainly roses but also tulips, can be picked from a conveyor belt and placed with conveyor tracking.

The solution is based on the fact that one person is needed to operate three robots. That means that one person is removing the cartons which may or may not be wrapped around the flower buds for protection.

The person in question checks whether the buds are undamaged whereafter the operator places the flowers on the conveyor belt.

“These flowers will be picked up by the robot at a stunning maximum rate of 2.1 seconds per cycle!”

Whereafter the flowers will be laid down on the conveyor belt meant for the sleeving machine.

Our search for improvement

But we didn’t stop there. We wanted more, we wanted to challenge the impossible…

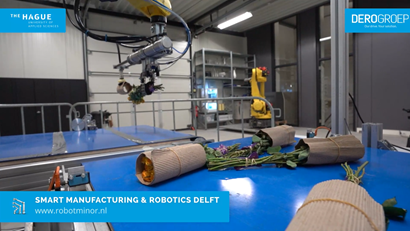

We wanted to achieve a solution where the operator directly puts the box or a handful of flowers directly on the conveyor belt.

In this case, the flowers will still have the cartons wrapped around the flower buds and will lay on top of each other. Which implements a new factor… which is height!

“We wanted to challenge the impossible”

We’ve used an 3D Intel® RealSense™ D415 camera. With our Open-CV based image processing

algorithm we’ve created a layer by layer flower detection.

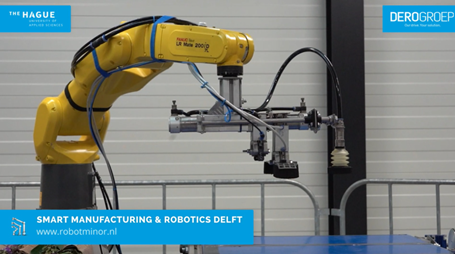

With our developed end-of-arm tool, specific for this task, we could grab the flowers from the stack.

Whereafter the carton can be removed by the same end-of-arm tool.

These dry cartons are picked with our vacuum gripper. The gripper is specially designed not to damage the flowers during the action of picking and minimally impact the cycle time.

“ With our Open-CV based image processing

algorithm we’ve created a layer by layer flower detection.”

Even tough this solution can only be used for dry and firm cartons, we believe it’s a step towards a more advanced solution for the problem.

Introducing our masterminds!

So you might think, who were the masterminds behind this project? From left to right we have Maarten van Geest, Arjan van der Knaap, Daniel Tacoma and Jelle van Haaster. Four excellent minor students who, through determination and close collaboration have created an innovative solution for the costumers needs.

Let’s connect!

Maarten van Geest: Maarten van Geest | LinkedIn

Arjan van der Knaap: Arjan Van Der Knaap | LinkedIn

Daniel Tacoma: Daniel Tacoma | LinkedIn

Jelle van Haaster: Jelle van Haaster | LinkedIn