Students: Roshan Gangapersad, Roy Osephius, Mick Remmerswaal, Alex van de Vliert

Introduction

This project has been carried out for Lencon Engineering in Noordwijk. Lencon Engineering is a flexible all-round engineering company that provides support in Engineering and Product development, but also in setting up assembly and production of their products. Lencon is fully organized to do this inhouse or by outsourcing engineers to their clients.

One of the projects Lencon is currently working on, is the development and production of a compact wearable ECG Heart monitoring device. This device consists of two plastic parts that need to be glued together watertight with specific medically approved glue. This process is unreliable when done by hand because of the high requirements of the end result. By automating this process our team wants to make it more reliable while complying with the medical standards.

Challenges

Challenges

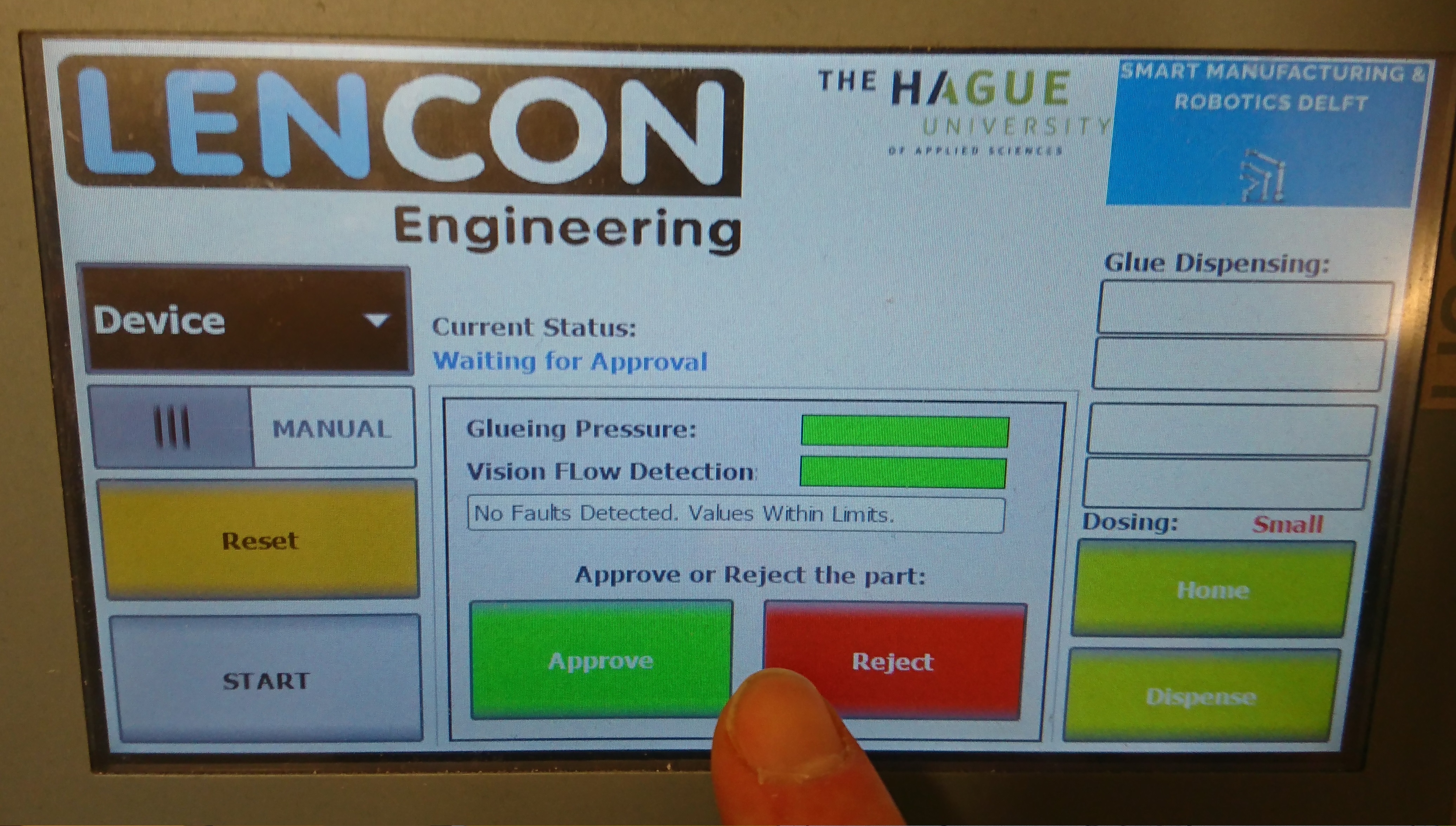

To comply with the medical standards every part needs to be checked and approved accompanied by the necessary paperwork. This means the production of these parts will not be fully automated and the system will be operated during the whole process. Production numbers are also not very high and the reason to automate the process is not to increase production. The biggest problem when applying glue by hand is consistency. The glue needs to be evenly spread to make it watertight and no excess glue is allowed on the outside of the part. This will result in rejected parts that need to be thrown away. Therefore the main goal of the assignment is to make the process more reliable and produce more consistent results.

The challenges during this project where:

– Being precise and consistent. A small amount of glue needs to be spread evenly across a small area. This has to be repeated with the same precision for every part.

– Finding a way to check the quality of the glue trail before it gets placed on the other half, and predict if it will be watertight without excess glue.

Solution

A robotic arm picks up the top half of the part and moves it under a stationary needle that dispenses the glue. After gluing, the robot moves the part to a check position where the glue trail will be checked. When the gluing process was found successful the part is placed on the bottom half of the part. When the gluing process was found faulty the part gets rejected.

The required precision is obtained in two ways:

– The parts are placed in slots by the operator and are picked up by specific end of arm tools for every part. This ensures the part is exactly in the correct orientation every time.

– Dispensing glue in the conventional way using air pressure is not precise enough for this application. The team had to develop their own linear actuating system that can dispense the glue very slowly and consistently.

A lot of research has been done on detecting the glue trail to check if the trail is consistent and predict if the part will be watertight. Together with a specialist in the field, it has been found that this will not be possible without altering the glue. For this reason, the team decided to present two solutions:

– Th e alternative solution is monitoring and controlling the gluing process. And make a prediction based on the parameters measured during the process. With the pressure applied during dispensing combined with a camera that checks if there is a constant flow coming from the needle, the quality of the glue trail is estimated.

e alternative solution is monitoring and controlling the gluing process. And make a prediction based on the parameters measured during the process. With the pressure applied during dispensing combined with a camera that checks if there is a constant flow coming from the needle, the quality of the glue trail is estimated.

– Beside the main solution, the team has presented a solution to be used with higher contrasting glue. This solution uses a vision system to check the consistency of the glue trail after it has been applied. If the use of high contrasting glue is possible, this is the preferable solution.