Adriaan Meijer, Kay Blokland, Loukas Leftheriotis, Tijmen Feitz, Viktor Wenemoser (2024)

Ter Laak Orchids Implements Groundbreaking Stick Placement Robot

Automatically Placing Support Sticks

This robot will be implemented on November 7th.

Designed for commercial orchid growers, this revolutionary robot automates the labor-intensive task of placing support sticks, offering a faster and cheaper solution.

Summary

The new robot is equipped with advanced technology that picks up support sticks from a box, attaches clips, and measures the stick’s deflection. This ensures precise placement by correcting any deviation. The system complements the automatic orchid sticking system developed as part of the 2018 SMR project, accelerating the process while significantly cutting labor costs. By automating this task, growers can focus on more valuable operations, enhancing overall productivity.

Problem

For commercial orchid growers, manually placing support sticks in plant pots is both time-consuming and labor-intensive. This repetitive task increases production costs and creates dependency on human labor, which can be unreliable due to absenteeism or illness.

Solution

Ter Laak Orchids’ new robot automates the entire process, from picking up support sticks to accurately placing them, thanks to its deflection measurement technology. The robot works efficiently, handling up to 120 sticks per hour without interruption. This automation reduces the need for manual labor, streamlines operations, and boosts productivity.

How to Get Started

Getting started with the support stick placement robot is simple. Customers can contact our team and our experts will guide them through installation and setup, ensuring a seamless integration into their existing processes.

“In a short time this group managed to create a working solution for part of a larger problem” – Ewald de Koning, Manager Innovation & Sustainability at Ter Laak orchids

Article:

To realise this we use machine vision to detect the tips of the stick and measure the deflection using the Pythagorean theorem. This deflection is then used to correct in the movement of the robot and increase accuracy of the placing of the stick. The sticks are photographed from two angles to ensure the deflection is measured correctly.

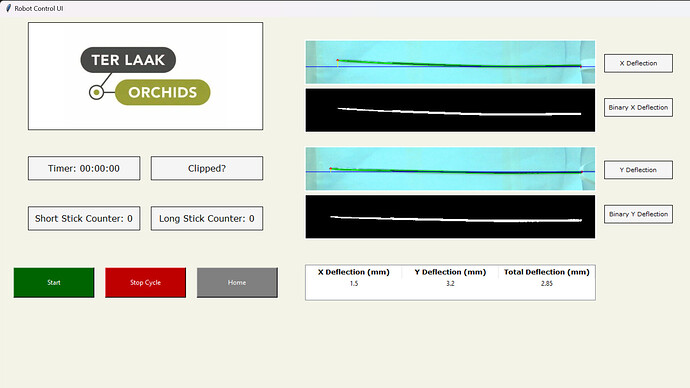

We have built a GUI to control the robot, as you can see in the picture below.

As you can see there are three buttons. The start button starts the robot and the timer. The UI also displays how many short sticks and how many long sticks have been placed since start was pressed. For each stick the UI also shows if the stick was clipped correctly.

The Stop Cycle button stops the timer and stops the robot after placing the stick it has already picked up. After placing its last stick the counter resets.

On the right the images from the vision are displayed and below that in the table you can see the measured deflection in mm from each angle separately and the total deflection.