Student: Laurens Roos

Introduction

In order to enable remote robotics education, the Workshop Universal at the Hague University of Applied sciences contacted us to build and design a robot that can be easily manufactured with limited material and tools.

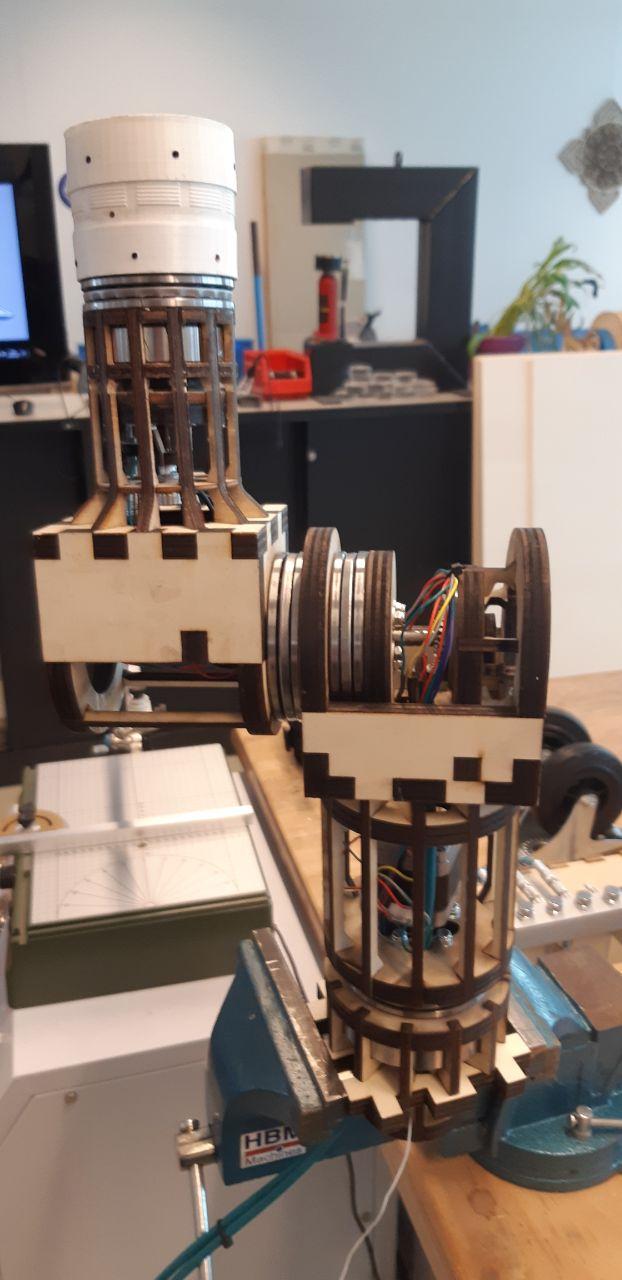

The big selling point of the kit robot is the only prerequisite of the robot being a laser machine able to cut 12 mm Multiplex

Current situation

Currently Covid-19 requires students to work from home and the Dutch government is preparing a one-and-a-half-meter Society. This requires new ways in how to give students opportunities to grow and develop. Currently there is no laid-out plan on how to let students run a group project that involve robotics and industrial control applications

The goal

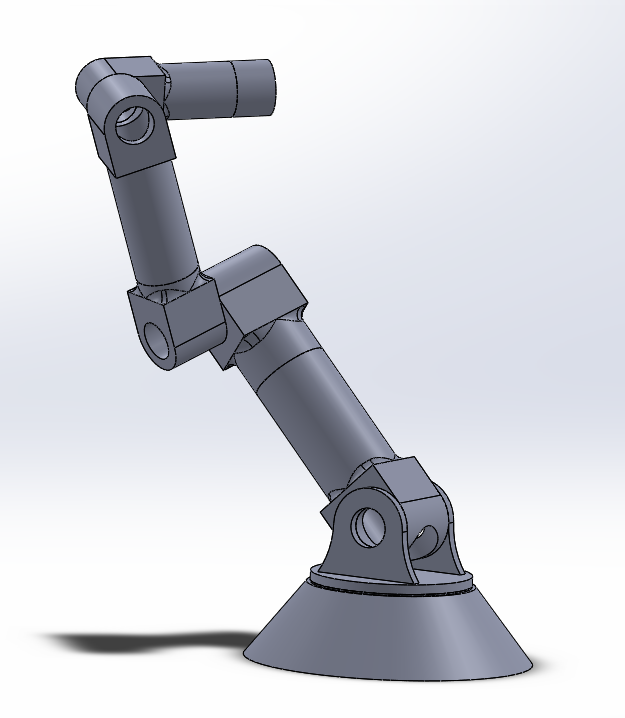

The goal is to make a fully functioning robot with a frame laser cut. This will be the prototype version that would be used to test the concept. A second version will be required before the concept can be officially launched

Challenges

The kit robot is finding the limits of what is possible with laminated wood, to allow for high tolerances with also a lightweight construction that can be easily assembled with a various level of skill from the student.

Our solution

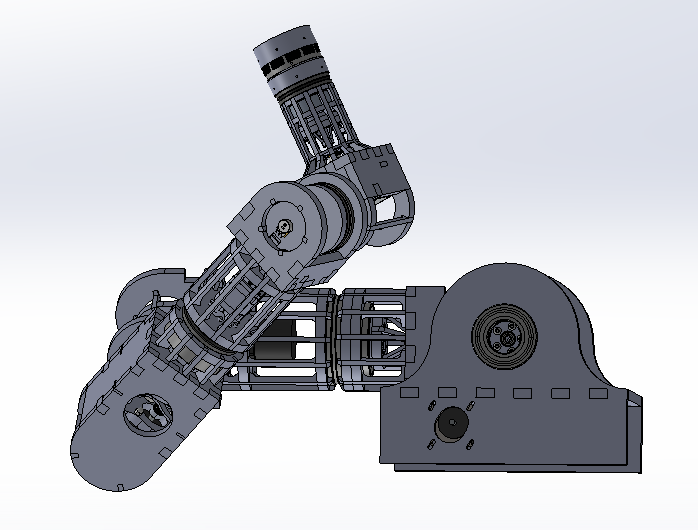

our solution makes use of a Multi-spline Cylindrical shape to allow for easy load spreading through the laminated wood structure. The Shape limits the shear points of the robot allowing safer operation. The prototype can be moved via the robot’s teach pendant. With further development we offer a robot with the following main skill levels:

Introduction level: (HIGH SCHOOL, Freshman University)

Arduino controller with preassembled parts and effector. The university or school in question buys all the parts preassembled and gives it to the students. They can directly program the robot with the Arduino IDE as introduction to robotics.

Intermediate level: (Freshman University, Second year student)

Student must assemble the robot themselves and they use a premade end effector. The students can program the robot with Arduino and/or Raspberry pi. They will learn assembly processes and how to work with near Realtime systems

Mechanical engineer level: (mechanical engineering students)

The bearings will be replaced by lower in weight and higher performance brass bushings requiring lathe work to be done. The students will learn both how to program and design a robot plus ways and methods on how to turn high precision inner and outer diameters.

Multidisciplinary engineering half semester level: (team of: Mechanical-, Software-, Electrical-, Engineering student)

the robot is preassembled and works with the open PLC softPLC (or dedicated PLC) running with the Nividia jetson TX2 platform. Allowing state of the art machine vision and AI applications to be designed for the kit robot.

Multidisciplinary engineering full semester level: (team of: Mechanical-, Software-, Electrical-, Engineering student)

A team of engineers, builds, designs the robot arm as part of the project, design their own end effector to suit their application. They are expected to understand and modify the robot to best suit their wishes and choice between bearing or bushings. The team will learn everything that comes with robots, from the assembly to the PLC work and machine vision.

Major decisions

In order to make sure the robot was safe to use by students, we decided for the round shape with internal motors. this shape is being repeated through the whole design process with internal cables and an internal interface for connecting the multiple end effectors.

Conclusion

Further development is needed for the robot to meet the goals. Version 1 of the robot has some minor design issues that need to be resolved. Currently the two arms work but weight is an issue that need to be solved in the near future.