Students: Koen Brok, Job Hertog, Ryan Verbaan en Kjeld Vermeulen

Introduction

De Vreede Techniek is an automation company based in Berkel en Rodenrijs. They supply automation solutions for the greenhouse horticulture industry. They mostly focus on using robot arms for their automation setups.

Current problem

Fully grown plants need to be potted before being shipped to customers. These ceramic pots come on pallets. The pots are taken off the pallets by hand. This takes multiple people and some time to do so. It’s a very repetitive task and suitable for automation.

De Vreede Techniek wants a solution to do this automatically. From pallet to sorted into a plastic tray

Our solution

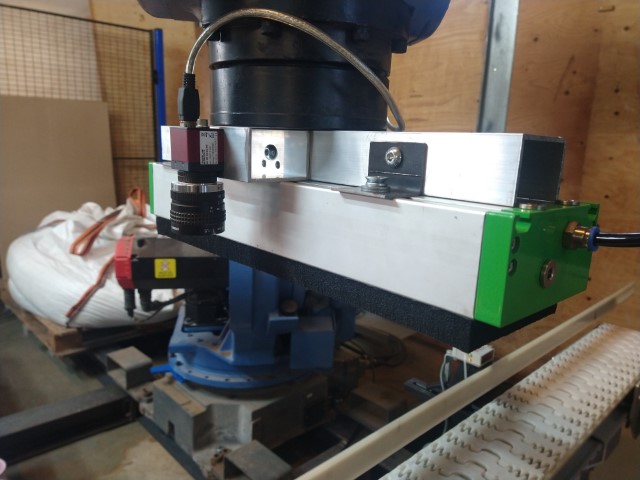

Our solution is centrally based around a Fanuc robot arm. The end of arm tool is a Piab Kenos gripper. This is a foam vacuum gripper. On the gripper sits a camera which is controlled by a Vicosys camera controller.

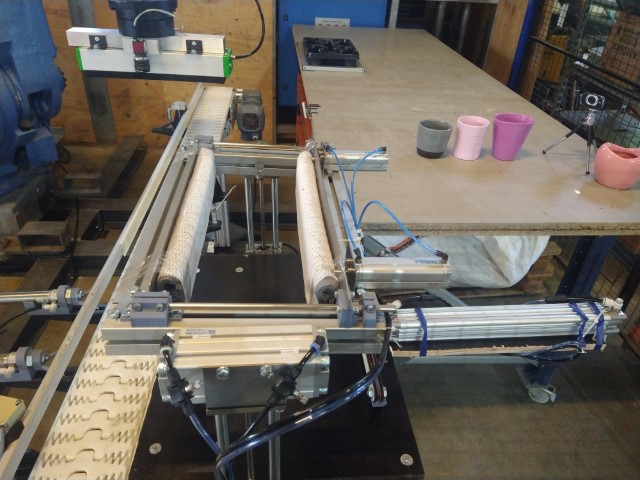

With a custom built flipping station, All pots are orientated correctly. All of this is being controlled with an Omron PLC with an intuitive hmi.

In front of the robot are the two pallets situated. These are the input positions.

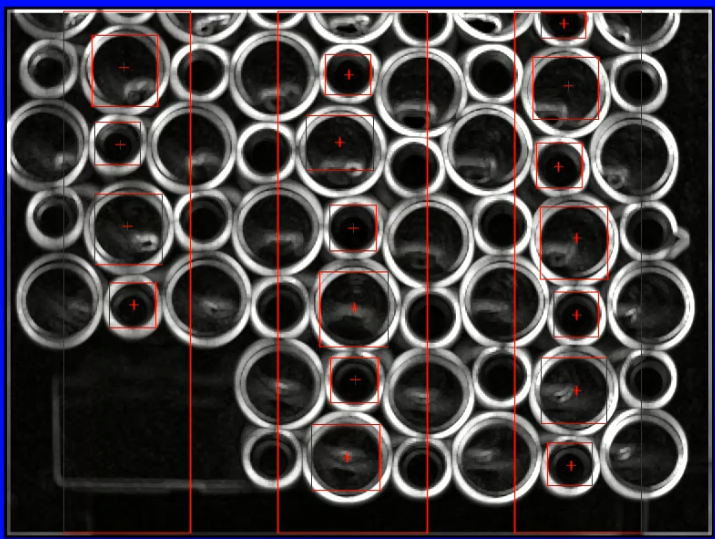

The robot first moves above the pallet and uses its camera to gather the position data of the pot. It also gathers where the upside down pots are located.

After gathering the pickup positions, the robot moves the pots to the input position of the flipper. This position changes based on where the upside down pots are.

The pots are placed on the input and the upside down pots are pushed inside the flipper. The right side up pots continue on the conveyor belt. After flipping the upside down pots they also continue on the conveyor belt.

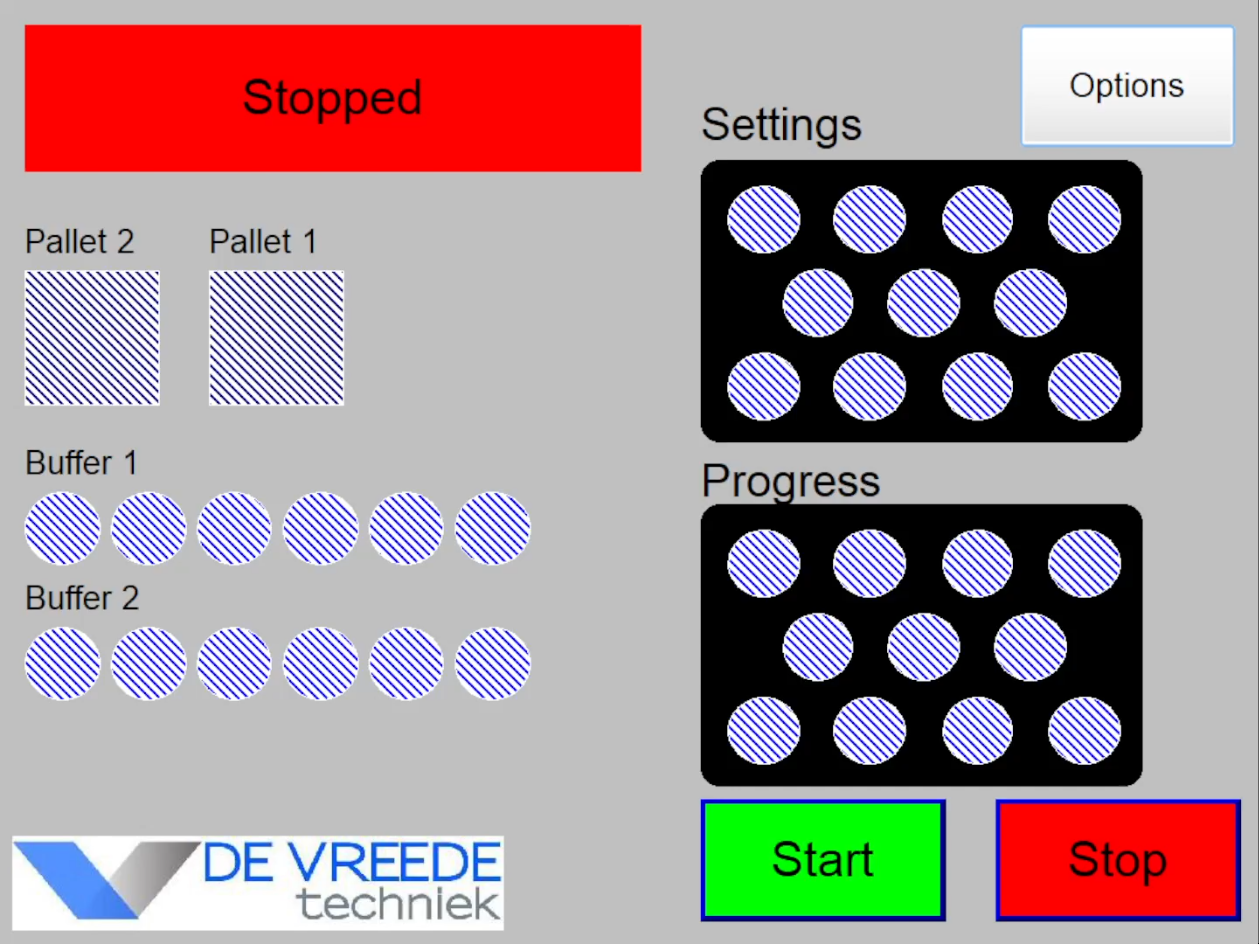

From the conveyor belt the pots are placed inside a buffer and from there they are placed inside a tray. That placing is based on the set positions on the HMI

Major decisions

One of the major decisions was how the pots would be flipped right side up. We looked at many solutions including; picking pots up from the side and flipping the end of arm tool or having a twisted conveyor belt. We decided on a separate clamping and flipping station based on pneumatics in the end. This for its ease of construction and possibility of increasing its size. Now five, 9 cm, pots fit inside but by making it longer more pots would fit.

Another major decision was the end of arm tool choice. We looked at a scissoring mechanism with suction cups for picking up the centre of the pots but we decided against it after seeing a demonstration of a foam gripper. That gripper gave a lot of room for flexibility in positioning and has a lot of gripping force on different types of plant pots.

Major highlight to this project was seeing the flip mechanism work in its entirety. The separate parts seemed promising but seeing the full sequence work was amazing.

Conclusion

We built a proof of concept of depalletizing and sorting plant pots using a robot arm. Using machine vision, a foam vacuum gripper and a custom flipping station we made sure the pots were sorted in the correct positions in the tray.

The total speed of this setup can be increased further by seperating the filling of the trays and depallitzing in two different robot sections.

Acknowledgements

We would like to thank Jasper, Anetta , Luuk en André from De Vreede Techniek for their help. They made sure we had a place to work with these industrial robots, gave us ample opportunity to learn from their expertise and answered all the questions we had.

We also like to extend our grattitude to our teachers, Thijs Brilleman and Mathijs van der Vegt, for their help during this project.