Jaap Knook : https://www.linkedin.com/in/jaap-knook-a8ba2b157/

René van Rijswijk : https://www.linkedin.com/in/ren%C3%A9-van-rijswijk-b79a0b170/

Tim Kuppens : https://www.linkedin.com/in/tim-kuppens-420798178/

Coen van Marrewijk : https://www.linkedin.com/in/coen-van-marrewijk-494886183/

Introduction

VDL TBP electronics is a company that is specialized in the manufacturing of small batch PCB’s (Printed Circuit Boards) for various big electronic companies around the world. They use state of the art pick and place machines from the company Mycronic to produce these PCB’s, and after production they have an in-house testing facility to make sure all produced PCB’s are of the desired quality.

Current situation

VDL TBP electronics produces small batch PCB’s, from which the average batch contains 50 PCB’s. This means a lot of various components are used each day. This also results in a lot of changing of components in the pick and place machine.

All components that will be used in a batch are placed in kits (See fig 1). These kits are put together by hand. All components come on a reel and these reels are stored in a storage location on the production floor. When the components are needed a worker retrieves the reel from a temporary storage and connects a feeder to it, after the feeder and reel are placed in a kit. And these kits are used in the production of the next batch.

The problem

Every time a reel is used in the production and is not needed anymore, the feeder is disconnected and the feeder and reel are placed back in storage. This is a time-consuming process, and it creates a loss in components every time the feeder is disconnected. Some reels are disconnected up to 70 times during its lifespan this gives a lot of lost components that could otherwise be used.

Our solution

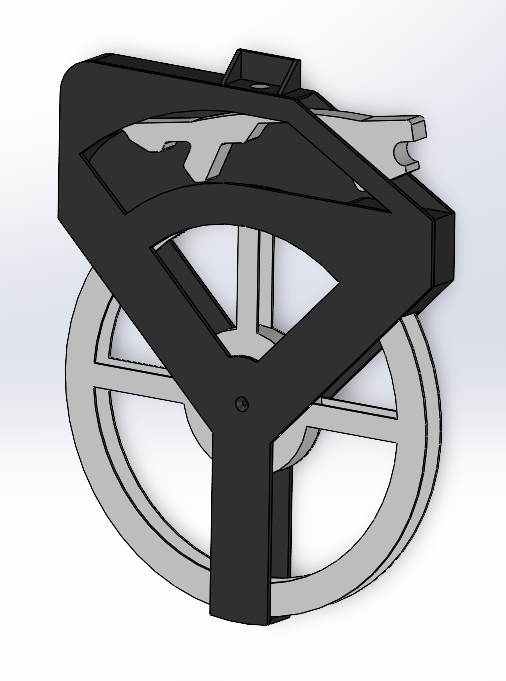

Our solution consists of making a cartridge (Fig.2) that will contain the reel and feeder together, so that the feeder will only have to be connected to the reel once. This cartridge makes it possible to grab and move the reel and feeder and keeping them together. This makes it possible to pick up the cartridges out of the kit and place them in a storage location. Once they are needed in the production process, they can be retrieved from the storage locations and placed in the correct bin locations.

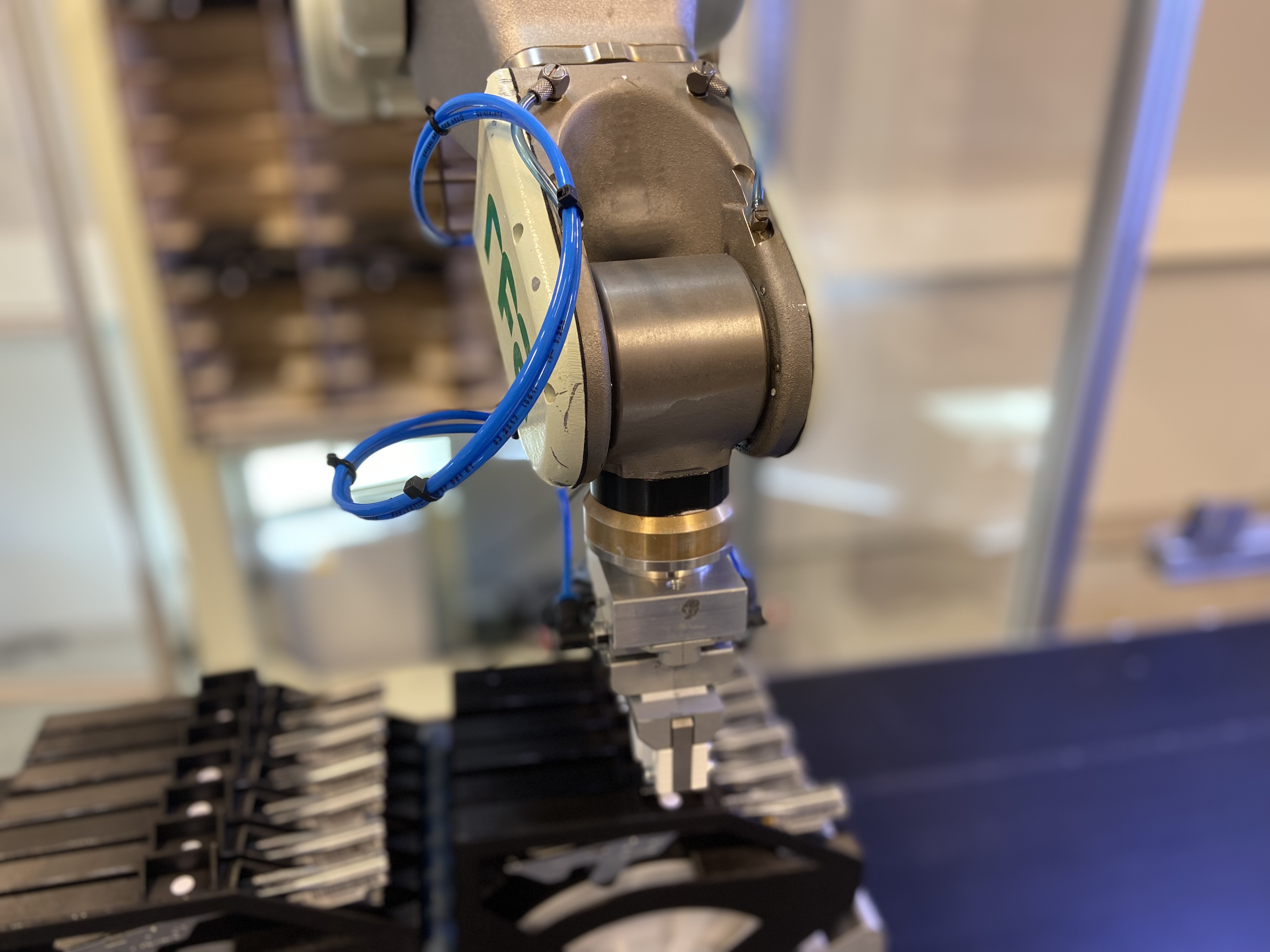

Using the Kawasaki FW03N robot (Fig.3) for pick and placing the cartridges in and out of the kit makes it a fully automated process.

To ensure that there will be a smooth working of the system we embedded a few vision cameras and a conveyor belt for transporting the kits. The vision cameras are used to scan the barcode on the front of the kit, scan the barcodes of the feeders and determine the location of the cartridges and the kitting bin (Fig.4). Scanning these barcodes means that the kitting can be done automatically and can be integrated with the current internal storage management system used by VDL TBP electronics. The barcodes are also used to double check and ensure the right cartridges go into the kits.

For storing the cartridges, we build a storage consisting of 36 spots where a cartridge can be stored. The cartridges inside incoming bins are scanned and then stored inside the storage. The program remembers the location of the cartridges and updates these locations while assembling the kits. When the incoming bin is empty the program looks through the currently stored cartridges and starts loading a bin once all cartridges are in storage.

The machine automates the kitting process and ensures that the feeder and component reels don’t have to be separated after production.

Conclusion

It can be concluded that the project meets all requirements of the client. The loss of components by assembling and disassembling is eliminated and the (un)kitting process fully automated. Furthermore, the machine is built so that it could be used in the real production facility of VDL TBP electronics.

For a team consisting of only mechanical engineers, it has been a real challenge to build a machine that is relying on a lot of electromechanical components. And a robot with which we all have never worked with.

Epilogue

We want to thank Klaas van Duin, Ronald de Jong from VDL TBP electronic and Michel Marqures from Mycronic. They have helped us by answering our questions throughout the designing and building process and with correctly defining the scope of the project.

We would also like to thank Mathijs van der Vegt and Thijs Brilleman for the technical support.